二硅化钼炉子的操作Operation of MoSiz furnace

浏览次数:3676 分类:技术文档

二硅化钼炉子的操作Operation of MoSiz furnace

1.炉子的干燥Drying of the furnace

新砌筑或长期不用的炉子在使用前需要干燥。一般干燥温度为100-200℃,而元件长期在低温下使用将会引起低温氧化。小型炉子干燥时间短,几个小时对元件影响不大。大型炉子干燥时间长,需要注意。为了通风,最好将炉门打开,随着温度升高可以半开,到1000℃以上完全关闭炉门。

The new built furnace or the furnace that haven’t been used for a long time should be driedbefore operation. The drying temperature generally is 100-200℃. The element that has been used for a long period under low temperature will cause low-temperature oxidation. For the small-sized furnace, as its drying time is short, several hours will affect the element little, but for the large-sized one,as its drying is long, it should be dried carefully.You’d better open the furnace gate to make it ventilated. The gate may be half-opened with therising of temperature and fully closed when the temperature rises above 1000℃.

2.炉子的启动Starting of the furnace

如果炉子干燥好了或不需要干燥就可以启动升温,为了避免过大电流冲击而使电器设备过荷,应采用下列步骤起动:

If the furnace has been dried or needn’t to be dried, then it may be started to raise temperature. In order to avoid that it is impacted by over current and the electric device is overloaded, the following steps should be adapted:

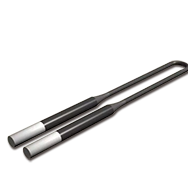

3.元件的更换Re3placing of element

在操作过程中发现元件损坏应首先确定位置,同时准备好组合元件。然后将损坏的元件夹头导线与母线连接的螺丝松开,清理开陶瓷棉,连用穿砖一起拔出来,再将新组合元件从炉顶插入,连接好导线,堵好陶瓷棉即可升温。

If it is found that one element is damaged during operating, firstly, you should determine where it is, at the same time prepare a made up one. Then loosen the thread which links the lead wire of the damaged element and the bus, clear out the ceramic cotton and pull out the through-brick. Afterward, insert the new element from the furnace top, link the lead wire, block the gap with ceramic cotton and start to raise temperaturenull

郑州焱帝高温炉业材料有限公司

郑州焱帝高温炉业材料有限公司

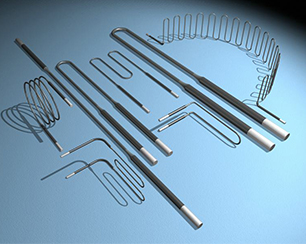

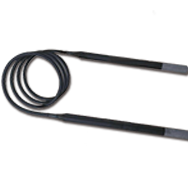

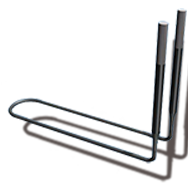

型硅碳棒元件.jpg)

型硅碳棒元件.jpg)

型硅碳棒元件.jpg)

型硅碳棒元件.jpg)

硅碳棒元件.jpg)

型硅碳棒元件.jpg)